Hydrojet - News

Donation handover of 10.000 Euro for the Tafel Bremerhaven

This is a "warm rain" for the Tafel Bremerhaven: Gerhard Dorandt, owner of the company Hydrojet Dorandt (in the picture second from left), delivered a donation check for 10,000 euros. Manfred Jabs, Reiner Giese and Gaby Treschok (from left to right) were delighted on behalf of the Tafel. The board members of Bremerhaven Volkshilfe, the organization responsible for the Tafel, also expressed their sincere thanks (from right): Viola Müller-Krause (Die Paritäten), Chairwoman Antje Alberts (Arbeiterwohlfahrt Bremerhaven) and Thorsten Büsker (Diakonie Bremerhaven). The company Hydrojet Dorandt, known for mobile waterjet and waterjet cutting technology at the highest safety level, was the talk of the town a few months ago with the removal of the pier tower.

Dismantling the dome of the Bremerhaven pier tower

Salvage of the dome of the Molenturm in Bremerhaven. The dome will be detached from the structure with a high-pressure water jet. For this purpose, a rail is laid under the dome on which water jets are mounted. The pressure of the water will slowly loosen the dome. On Monday, the preparations for this apparently turned out to be more difficult than expected. If it is possible to detach the dome from the pier tower, it will be removed in the course of the week.

Motorway rehabilitation in the shortest possible time with Hydrojet Dorandt

Motorway rehabilitation in the shortest possible time with Hydrojet Dorandt through the use of 50 removal robots.

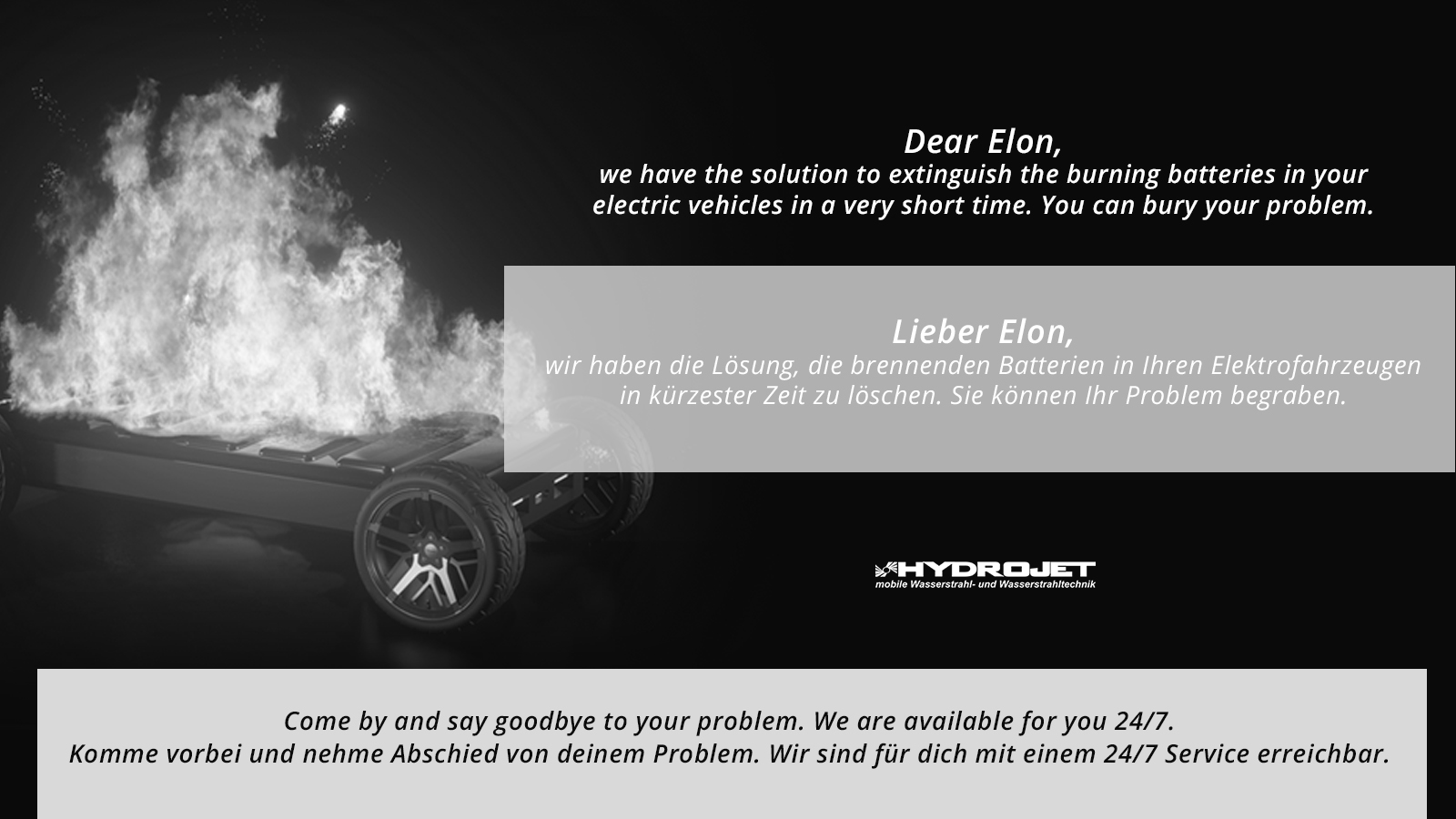

Extinguish burning e-car batteries.

Dear Elon,

we have the solution to extinguish the burning batteries in your

electric vehicles

in a very short time. You can bury your problem. Come by and say goodbye to your problem. We are available for you 24/7.

Performance upgrade "generator sheet package" successful

By using waterjet technology, the performance of a generator sheet package was able to meet the customer's requirements.

By using the technology of water jet cutting, which had not been tested for this purpose, it was possible to modify a stator core in such a way that customer requirements could be met. Additional slots had to be made in the staircase of a generator laminated core so that the voltage of the electrical fields is such that the staircase area of the laminated core and the stator winding inside it do not reach temperatures so high that the generator can deliver more power.

YOU HAVE QUESTIONS?

need information

or counselling?

or simply call us

24/7 service

+49 (0) 170 4054925

+49 (0) 176 227 68053

Contact

Hydrojet Dorandt

Nordring 3 | D 49328 Melle

Phone:

Mobile:

E-Mail: