Hydro-cutting | Water jet cutting with maximum pressure directly on location

Hydro-Cutting

Abrasive cutting with ultra-high pressure water jet up to 6000 bar stationary and 3000 bar mobile.The Hydrojet water jet cutting technology is suitable for cutting almost all materials. Special nozzles and environmentally friendly low-pressure water technology are used. Automatic, remote-controlled systems ensure fast and ultra-exact waterjet cutting of materials without erosion.

The waterjet technique can be used in all environments, especially in safety-sensitive areas. As it is a "cold" process, there is no sparking or thermal reactions. Working in Ex-areas is therefore possible. Cutting with waterjet technology is predestined for use in inhabited buildings or areas that are sensitive to dust and vibrations.

Advantages of the hydrojet waterjet cutting technology

- Waterjet cutting enables fast ultra-exact cuts without erosion.

- Automatic systems at the highest safety level

- spark free cutting

- No thermal reactions

- Can be used almost everywhere

- Reduction of noise emission to a minimum level

- Cutting in explosion areas (Ex zone) possible

Areas of application

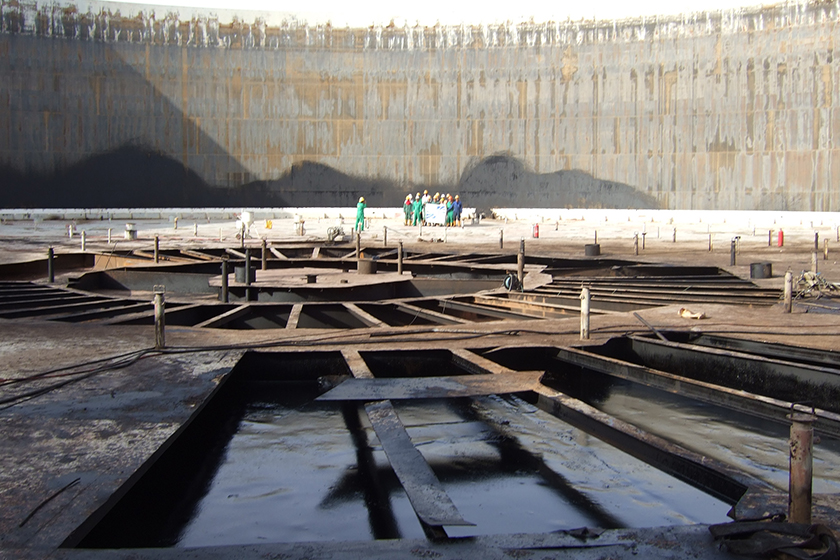

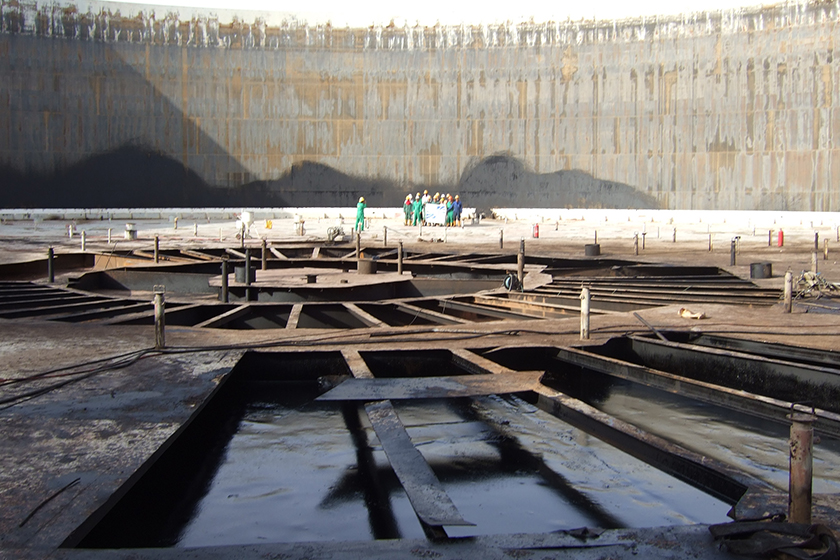

Water jet cutting of tanks, cutting work in Ex zones, civil engineering, road construction, cutting of stone slabs

MICRO - CUTTING

mobile micro waterjet cutting

Our new MIKRO-CUTTING process enables mobile waterjet cutting with unprecedented efficiency while greatly reducing the amount of water. Compared to other waterjet processes, the amount of water is reduced by up to 90 %. As with every mobile waterjet process offered by HYDROJET DORANDT, MIKRO-CUTTING is also carried out with automatic, remote-controlled and pneumatically-guided cutting carriages, which enable accident-free working.

The combination of a cold cutting process with a water-abrasive mixture, a small amount of water and the pneumatically guided cutting carriage enables explosion-protected work even in difficult-to-reach and moisture-sensitive working environments. Precision cuts on straight surfaces, pipes and also circular cuts are possible.

Due to the high working pressure, it is possible to cleanly separate materials of almost any thickness. The materials that can be separated include: Steel, stainless steel, titanium, aluminium, copper, nickel and cobalt-nickel.

Our use of modern, compact electric pumps with low noise levels allows the pump equipment to be used inside buildings. This enables space-saving, environmentally friendly work with short hose routes.

Advantages of mobile micro waterjet cutting

- is carried out automatically, pneumatically and remotely controlled, as with any mobile water jet cutting system.

- Cold cutting process without bending materials such as steel, titanium, aluminium, copper, nickel etc.

- each material thickness is separable

- Mobile micro waterjet cutting for use in hard-to-reach areas

- Extremely small amounts of water allow separation possibilities in sensitive areas

- Small and precise cutting widths create low material removal during the cutting process

- Fast installation with short hose lengths generate little pressure loss

- sustainable cutting with pumps in electric mode

Hydro-Cutting | Rotor Blades

Hydro-Cutting rotor blades (2500 bar), mobile ultra-high pressure water jetting Hydro-Cutting for rotor blades With our special low-water pumps< we can cut rotor blades based on glass-fibre reinforced plastic (GRP) on site and in the absence of a water supply.

Thanks to state-of-the-art equipment, we are able to cut GRP parts without the addition of abrasives. Only water is used without any chemical additives. In addition, no dangerous heat is generated due to the cold cutting process. Furthermore, the separation of smallest parts into the air is prevented, which enables clean working.

Modern, mobile HDW units are used, which operate quietly due to the existing, high-quality sound insulation. These systems meet the highest safety standards worldwide.

Your advantages of hydro-cutting for GfK rotor blades at a glance:

- Largely independent of the infrastructural situation due to few water pumps

- Clean work due to the exclusive use of industrial water without chemical additives

- No dust formation due to cold and precise cutting

- Low-noise due to new, sound-proofed, mobile HDW pump systems

- Safe working due to remote-controlled, automatic cutters

- Modern pumps with highest safety standards

YOU HAVE QUESTIONS?

need information

or counselling?

or simply call us

24/7 service

+49 (0) 170 4054925

+49 (0) 176 227 68053

Contact

Hydrojet Dorandt

Nordring 3 | D 49328 Melle

Phone:

Mobile:

E-Mail: